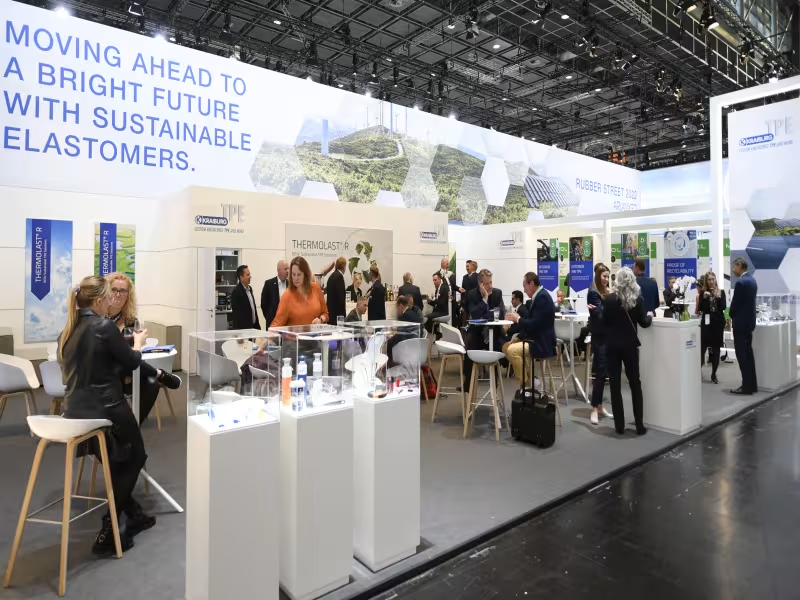

SHERIDAN, WYOMING – October 9, 2025 – K 2025 will again make Düsseldorf the center of gravity for plastics and rubber next week, and “Rubber Street” in Hall 6 is set to be one of the show’s most concentrated hubs for elastomer innovation. Jointly organized by the German Rubber Manufacturers Association (wdk) and Messe Düsseldorf, the dedicated zone brings the full elastomer value chain into one 500 m² area—showcasing materials, compounding, processing, testing, and recycling with a sharper emphasis on thermoplastic elastomers (TPE) and circularity.

Why Rubber Street matters for the value chain

Rubber Street’s remit now stretches from raw-material suppliers to processors, institutes, networks, and recyclers, giving buyers and engineers a single, curated corridor to benchmark offerings. For OEMs in transportation, industrial goods, consumer products, and building systems, the benefit is speed: faster supplier discovery, quicker comparison of elastomer and TPE options, and clearer visibility into sustainability-ready formulations that can move from pilot to production.

TPE momentum meets classic elastomers

The exhibitor profile reflects how TPE has matured into a mainstream choice alongside cross-linkable elastomers. Visitors will see innovations spanning both families—soft-touch and overmoulding-friendly TPEs on one end, and high-performance, cross-linked rubber solutions on the other—positioned for applications from sealing and damping to wear resistance and chemical compatibility. For developers balancing performance, processability, and recyclability, the Street provides a practical map of trade-offs and hybrid approaches.

Circular economy—demonstrated underfoot

Sustainability moves from panel talk to practice this year: Rubber Street will use a flooring system made from recycled tyre rubber, installed via a puzzle-click format that resists slippage, cleans easily, and can be redeployed show after show. The concept underscores two procurement angles that are increasingly non-negotiable in vendor evaluations: durability in use and circularity at end-of-life. For stand builders and exhibitors, the ability to reuse and ultimately recycle the mats improves carbon accounting without sacrificing visitor comfort.

What visitors can expect in Hall 6

- A fully booked showcase with 19 main and sub-exhibitors covering the elastomer and TPE supply chain.

- Compounds and additives positioned for high-throughput processing and quality control.

- Processor know-how on tooling, mixing, and line integration to reduce scrap and speed changeovers.

- Research partners and networks highlighting testing methods, compliance routes, and recycling pathways.

- On-site sustainability proof points—from recycled materials to design-for-disassembly narratives.

Industry context: performance, compliance, and speed-to-launch

Across segments, purchasing criteria are converging on three axes: (1) demonstrable performance in real conditions, (2) a credible path to compliance and end-of-life recovery, and (3) shorter engineering cycles. Rubber Street aligns with that shift. By concentrating raw materials, compounders, and recyclers together, the zone helps engineering and sourcing teams compress sampling, validation, and supplier qualification into a tighter window—particularly useful for programs facing 2026–2027 model deadlines or customer sustainability scorecards.

Quote from the organizers

"We are delighted that Messe Düsseldorf is showing a clear commitment to rubber and elastomers at K and is giving Rubber Street 2025 a prominent place in the trade fair programme. This is a strong signal for our entire industry and for visitors who want to find out about innovations in the elastomer sector at the trade fair," said Boris Engelhardt, Managing Director of the wdk.

Strategic takeaways for buyers and engineering teams

For procurement and R&D leads, the Street offers a low-friction way to compare rubber and TPE routes for the same function—sealing, vibration isolation, or tactile surfaces—and to evaluate recycled content and recyclability claims head-to-head. Teams can leave with: a shortlist of process-ready compounds, contacts for reclamation or closed-loop pilots, and a clearer integration path for elastomer-to-TPE conversions where cycle time, weight, or multi-material bonding favors TPE. (See more in our K 2025 coverage.)

How to attend

K 2025 runs Wednesday, 8 October through Wednesday, 15 October, 10:00–18:30 daily, at Messe Düsseldorf. Rubber Street is located in Hall 6. Day tickets and multi-day passes are available, with reduced pricing for pupils and students.

A curated, end-to-end lens on elastomers and TPE—backed by visible circular-economy practice—makes Rubber Street a high-yield stop for decision-makers aiming to accelerate materials selection, compliance readiness, and sustainable product design.

Concise summary with brand, technology, and benefit: Rubber Street at K 2025 unites elastomer and TPE innovation with real circularity demos, helping OEMs speed materials selection and sustainability.

elastomer innovation, thermoplastic elastomers, TPE at K 2025, Rubber Street Hall 6, circular economy in rubber, recycled tyre materials, wdk Messe Düsseldorf, elastomer recycling