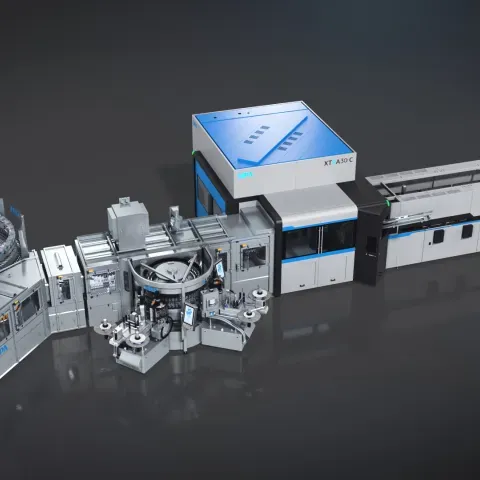

SHERIDAN, WYOMING – October 15, 2025 – SIPA has introduced the Sincro Tribloc, a fully integrated PET bottling solution that combines blowing, labelling, and filling in one compact unit. Designed for ultra-high-speed operations of up to 90,000 bottles per hour, the system redefines efficiency and sustainability standards for beverage manufacturers seeking leaner production and reduced total cost of ownership.

Compact Integration for Maximum Efficiency

At the core of SIPA’s Sincro Tribloc is a seamless connection between three advanced systems—the XTRA rotary blower, the XLABL roll-fed labeller, and the FLEXTRONIC filler/capper. By eliminating intermediate conveyors, the design minimizes space requirements, simplifies line management, and cuts operational costs. The integrated block reduces energy consumption and enhances hygiene, making it ideal for high-volume beverage producers transitioning toward smarter, more sustainable operations.

High-Speed Blowing with XTRA Precision

The Sincro Tribloc’s XTRA 30 COMPACT rotary blower delivers exceptional output—3,000 bottles per hour per cavity—while maintaining precision in material distribution. Its 275° process angle ensures uniform wall thickness even in ultra-lightweight formats, such as 4.9 grams for a 0.5-liter bottle. With the built-in Oven Plus system, preform heating adapts dynamically to ambient conditions, improving thermal control and minimizing scrap. The result is reliable, high-speed production with consistent bottle quality across every cycle.

Seamless Labelling Performance at Full Line Speed

The XLABL roll-fed labeller sustains uninterrupted operation through its automatic reel splicing mechanism and straight-blade cutting system—engineered to withstand up to 200 million cuts. The precision handling system ensures accurate label placement even on extremely lightweight bottles, which are stabilized using sterile air pressurization. This single labeller maintains the line’s maximum 90,000-bottle-per-hour output while reducing maintenance downtime, thanks to its ergonomic design and tool-free component replacement.

Flexible, Hygienic Filling and Capping with FLEXTRONIC

SIPA’s FLEXTRONIC modular filler adds flexibility across beverage categories—from still water to carbonated soft drinks and hot-fill applications. Operating within a micro-isolator-protected environment, the filler guarantees hygienic performance for sensitive beverages. The XFILL setup integrates directly with upstream product preparation units, while its cap feeding system features buffering and anti-obstacle mechanisms to prevent stoppages. Optional quick-change necks and multiple cap-treatment choices further streamline production adaptability.

Sustainability and ROI: A Competitive Advantage

Engineered for long-term efficiency, the Sincro Tribloc achieves up to 95% line efficiency and as much as 15% savings in total operating costs. Its layout reduces plant floor space by up to 30% and supports full compatibility with 100% recycled PET (rPET). Producers benefit from fewer operators, faster changeovers, and lower energy use—delivering both economic and environmental gains. The enhanced accessibility, particularly around the labelling section, simplifies maintenance and daily operations.

Future-Proof Bottling for an Evolving Market

As beverage manufacturers worldwide adapt to circular economy goals and rising production demands, SIPA’s Sincro Tribloc positions itself as a future-ready investment. From preform to cap, every phase is engineered for speed, precision, and sustainability. The system offers an end-to-end solution for companies aiming to modernize facilities, improve energy efficiency, and stay ahead in competitive bottling markets.

Learn more about SIPA’s integrated bottling technologies at www.sipasolutions.com.