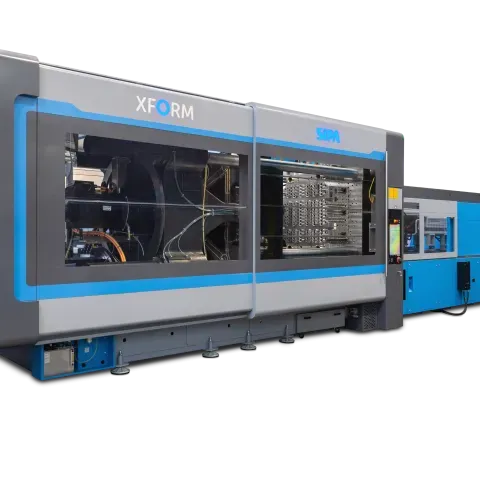

SHERIDAN, WYOMING – October 15, 2025 – SIPA has unveiled the XFORM PRO, a next-generation PET preform system that merges mechanical innovation with digital intelligence. Building on the success of the XFORM Gen 4, the new platform delivers faster cycles, lower energy use, and seamless integration with the company’s new XBrain telemetric mold management system—marking a major leap forward in high-cavitation PET preform manufacturing.

Boosting Productivity in High-Cavitation Preform Production

The XFORM PRO builds on SIPA’s well-established legacy in PET preform molding, advancing its capabilities across performance, precision, and sustainability. Designed for molds up to 200 cavities, the system increases throughput with a 10% reduction in cycle time while maintaining preform quality. The new ICE (Internal Cooling and Extraction) system provides optimized thermal control, supporting faster, more consistent cooling and enhanced part uniformity.

Key performance highlights include:

- 10% shorter cycle times, increasing productivity and reducing time-to-market

- 6% lower energy consumption, contributing to more sustainable production

- 7% improved lock-to-lock performance, delivering tighter tolerances and reduced waste

- Vertical preform take-out system, enabling additional cooling and higher overall output

These advancements make the XFORM PRO particularly attractive for large-scale converters producing beverage packaging and personal care preforms where uptime, precision, and cost efficiency are critical.

Enhancing Operator Safety and Operational Continuity

SIPA has also focused on human factors. The XFORM PRO introduces a redesigned, ergonomic cabin that enhances operator comfort while integrating new safety mechanisms. In high-volume, continuous production environments, these safety improvements reduce operator fatigue and improve overall workflow reliability.

Sustainability as a Competitive Advantage

With sustainability now a top purchasing criterion across packaging supply chains, the XFORM PRO’s 6% energy reduction plays directly into manufacturers’ ESG objectives. Reduced energy consumption, combined with longer mold lifespans and predictive maintenance, contributes to lower total cost of ownership (TCO) and smaller environmental impact—critical differentiators for global brands seeking greener operations.

XBrain: Digital Intelligence for Smart Mold Management

Complementing the hardware evolution, SIPA introduces XBrain, a cloud-connected mold management platform that digitizes production oversight and predictive maintenance. Integrated directly with XFORM PRO, XBrain tracks every operational metric—from cycle counts and uptime to maintenance history—providing operators with real-time data via smartphone or tablet.

Connectivity is ensured through Bluetooth 5.0 and NFC, linking to the SIPA Echo Cloud and Echo Web Portal, where advanced analytics and lifecycle insights support smarter decision-making. The system works across SIPA and non-SIPA machines, ensuring compatibility for mixed-production environments.

“Every mold equipped with XBrain can communicate vital information—including cycle counts, working hours, and historical performance data—directly to the operator via smartphone or tablet,” the company stated. This transparency enables proactive rather than reactive maintenance, minimizing downtime and ensuring consistent quality across large-scale operations.

Real-Time Insights and Predictive Maintenance

XBrain provides manufacturers with:

- Lifecycle tracking of tooling components with digital part manuals and direct online ordering

- Predictive maintenance capabilities to anticipate wear before failure

- Real-time performance monitoring to reduce downtime and improve quality assurance

- Secure data storage and analytics for long-term performance benchmarking

By merging mechanical innovation with digital intelligence, SIPA positions XFORM PRO and XBrain as a combined solution for next-generation PET preform production—faster, more sustainable, and data-driven.

Strategic Outlook for the PET Packaging Industry

As consumer packaging demand grows amid sustainability and efficiency pressures, high-cavitation systems like XFORM PRO give converters a decisive advantage. Integrated intelligence through XBrain will further shape the shift toward Industry 4.0-ready production, where data transparency, energy efficiency, and predictive maintenance define competitiveness.

Learn more about SIPA’s latest innovations at www.sipa.it.